See this post for the externalities tear down to get the engine out of the machine.

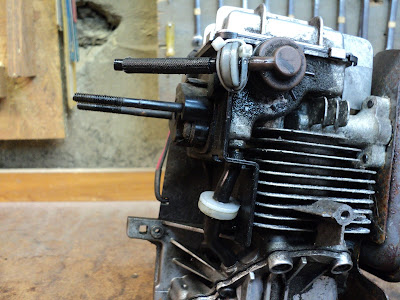

Here's a view of the engine.

I'm only tearing down this engine for amusement. No internal parts are available for it -- an overhaul is not on. I'm just curious about how it looks inside; it has almost no compression, and won't sustain operation at wide open throttle.

So, here goes a step-by-step tear down, for what it's worth.

1) Drain The Oil

2) Air Cleaner Body

- Crankcase ventilation tube off of nipple at top of air cleaner body.

- Primer suction tube off of nipple at right side of carburetor.

- Two M5 prevailing torque hex nuts (8mm A/F).

3) Carburetor & Gasket

They're free to just come off.

4) Breather Check Valves & Tubing

Note the directionality of the two check valves. Each valve's conical end points in the direction of flow.

5) Carburetor Heat Dam, Baffle & Gasket

Two M5x22mm washerhead screws (T25 Torx recess).

The screws were installed with threadlocker, and will take some effort to remove.

The gasket will likely be firmly stuck to the cylinder head.

6) Muffler & Gasket/Heat-Shield

Three M5x38mm truss head screws w/split lockwashers (T25 Torx recess).

7) Spark Plug

It's a Champion RY4C -- 5/8" A/F; 0.025" gap.

8) Ignition Module

I don't have a gap figure for it. It measures about 0.008".

9) Flywheel

A 3", two-jaw puller gets it off nicely.

10) Valve Train Cover & Gasket

One M4x27mm washerhead screw (T20 Torx recess).

11) Crankcase Cover

Nine M4x12mm cap screws (T20 Torx recess).

- - -

And here we have an engine that's well and truly done like dinner.

It's impossible to photograph well, but the cylinder wall scoring is horrific -- you can feel the ridges.

This engine must have been run out of oil. It's a wonder it was still able to run at all.

Conclusion

These little engines demand reasonably conscientious attention. A 65ml sump capacity leaves very little margin for neglect.

This particular engine came to an unfortunate end, but that's no reflection on the engine's quality of manufacture. These machines are jewels of precision engineering and construction, and ought to be treated accordingly.

# # #

# # #

No comments:

Post a Comment