[Last updated Wednesday, July 10, 2019.]

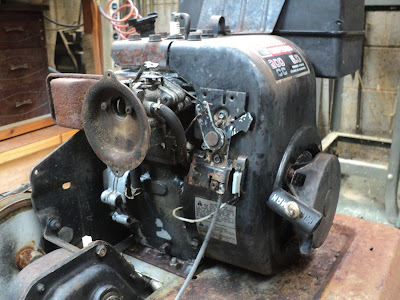

My son got me a roto-tiller to go to work on.

Model No. is C459 62337. Serial No. is 825998. (As best I can make them out.) Engine is a Tecumseh 200cc, 5.0hp.

The machine is very old and in rough shape. I can find nothing about it on the internet. The engine is said to be functional. The forward V-belt is a ruin. The reverse V-belt is missing, and the reverse drive mechanism has been monkeyed with to the point where I can't really see how it might operate. I have a nasty feeling that what I may have here is a collection of scrap metal bits.

- - -

Spark Plug

The spark plug is an NGK B4-LM. That's a 14mm non-resistive type with a screw-on terminal head and a 13/16" hex. With the paint lacquer-thinnered off of its ceramic, it looks to be in pretty good condition.

Gap is a snug 0.030". I tried my

spark tester on it, and couldn't see a spark. That may be because it's pretty bright outside, even in the shade. Also, the recoil starter is sluggish; that's not helping. I may as well attend to the recoil starter right now.

- - -

Recoil Starter

The starter is fastened by four 1/4"-28 x 3/8" pan head screws with captive external tooth lockwashers, No. 3 Phillips recess. A cordless impact wrench made short work out of getting the screws out.

With the starter off, I gave it a good WD-40ing, and dug some debris out of the starter cup.

With the starter reinstalled, its action is now better, but still not perfect -- rewind is balky at times. It has to be coaxed to rewind fully.

- - -

Recoil Starter Update --

SATURDAY, JULY 6, 2019

I discovered why the starter won't rewind consistently. The cord that's in it is not original. It's a replacement cord that's thicker than it ought to be for the depth of the pulley. When rewinding, the cord sometimes piles up on itself -- to the point where it jams against the starter's shell. The only sure fix would be to replace the cord with thinner material.

- - -

Further To Spark

With some further trial of the spark plug, I did see a spark a couple of times. The spark didn't look robust.

I tried closing down the spark plug's gap some, and that seemed to give some improvement, though spark still appears to be intermittent and lame.

- - -

A Start Attempt

The dipstick was showing very low oil, so I added some SAE 30. The fuel tank was empty, so I gave it some regular gasoline.

And it's no go. Not so much as a pop.

- - -

Inside The Workshop And Sparking In The Dark --

FRIDAY, JULY 5, 2019

I've brought the machine inside the workshop where I can douse the lights, and what spark there is is readily observable. It still doesn't seem consistent, though. Another problem that has surfaced is that the fuel line tubing is leaking. So, the cowl and the flywheel have to come off.

- - -

Cowl Removal

- Free the governed speed controller from the side of the cowl; two 10-32 x 1/2" hex washerhead screws, 1/4" A/F (across flats).

- At the top, three 5/16"-18 hex head screws, 1/2" A/F. Note that these are cylinder head screws that will have to be properly torqued to 200 in-lbs on final reinstallation.[1] Note also the steel loop held on by two of the screws -- a hoisting eye, possibly?

- Low down at either side -- a 5/16"-24 x 3/4" hex head screw with captive split lockwasher, 7/16" A/F with No. 3 Phillips recess.

With all that attended to, the cowl can be coaxed off the engine with judicious application of force where needed. And here's what was revealed when I got the cowl off.

A huge mouse nest. That would have played hell with engine cooling had I gotten the thing to run.

- - -

And A Great Big 'WHOOPS!'

Two of the three cylinder head screws broke off on me.

Now I'll have to remove the cylinder head to see what, if anything, can be done to repair that.

There's nothing like working on decrepit, derelict old gear. Nasty surprises are common.

- - -

Cylinder Head Off

The gasket is stuck to the block -- it's unlikely to be salvageable. I got three of the remaining five screws out whole, and broke off two more, so four out of eight screws are broken. This will be challenging.

- - -

Removing The Broken Screws Is A No Go --

SATURDAY, JULY 6, 2019

I tried Vise-Grips on one of the protruding screws. I tried heating up the block around the screw with a propane torch. 'Couldn't budge the screw.

I centre punched one of the screws that was broken off flush. 'Drilled it through with a 1/8" cobalt drill, then 3/16". When I tried 7/32", it was no go. The screws must be case-hardened ones, so their outermost material is too hard even for a cobalt drill.

A digression regarding the use of screw extractors: Screw extractors will work on broken off screws that aren't seized; they will not extract seized screws. All you'll do by applying a screw extractor to a seized screw is you'll break the extractor. Digression over.

So, there's no way that I can salvage the original 5/16"-18 female threads at the sites of the broken screws, and I can't bore out the sites for threaded inserts, which I can't afford anyway. I'll reinstall the cylinder head with only four screws; at least the pattern of the remaining good threaded holes is symmetrical. The head gasket came away from the block without damage, so I can reuse that. If I can get the engine running, the worst that can happen is that the cylinder head will blow off. More likely it will just spring a leak or leaks.

- - -

Flywheel Off

An impact wrench made short work of getting the 3/4" A/F flywheel nut off. A three-jaw puller got the flywheel off easily. And we can see the points-and-condenser ignition system. Filing the points and adjusting points gap to 0.020" might cure the intermittent spark problem. And while I have access to it, I'll replace that rotten fuel line tubing with new, 1/4" I.D. stuff that I have on hand.

- - -

And We Have Spark

The faces of the breaker points were completely black. The points weren't making consistently. I filed the points, reinstalled and gapped them and now I have consistent, fairly healthy spark. So it's on with dismantling and cleaning the carburetor.

- - -

Carburetor Cleaned, Adjusted and Reinstalled

The carburetor wasn't too bad inside. The mixture screws seemed to me to be set awfully lean, so I turned both of them 1 1/2 turns out for a starting point.

- - -

Start Trial

I got it to start and run for about one, maybe two seconds, then it died and refused to restart. I checked for spark and there is none. I'm suspicious of my filed points. I may have made it so they're not closing reliably. To be investigated.

- - -

Timing Is Gone

The points are making and breaking, but lo and behold, the flywheel's key has sheared right off.

That explains a lot. With the key sheared off, the flywheel moved out-of-time with respect to the breaker points cam, so spark was lost.

- - -

Progress Of A Sort --

SUNDAY, JULY 7, 2019

The sheared off key is a semicircular Woodruff key. I managed to fake a serviceable key from 1/8" square cross-section keystock.

The engine now starts, but only if Quick-Start is sprayed into the carburetor. It does run, but it hunts. I need to get the machine outside where I can run it all I want and fiddle with the mixture screws.

A trip to the small engines place in Pickering is in order. I'll get a proper Woodruff key, and see if they have a parts breakdown for this old machine -- see if belts are available for it.

- - -

New Woodruff Key Obtained --

TUESDAY, JULY 9, 2019

Here's a view of the new key alongside the old sheared off one.

Tecumseh P/N is 32589.

I also got a new 37" forward V-belt, a Continental Elite P/N 84370. I won't get the 41" reverse belt until I have the reverse drive selection mechanism figured out, which is looking like never.

- - -

As Done As It's Going To Get --

WEDNESDAY, JULY 10, 2019

It's exhibiting a more-or-less normal starting characteristic -- I no longer have to give it a shot of Quick Start to get it going. I've gotten the idle speed down to within reason, and the governor appears to be functioning well. It's still missing its air filter element; I'm not sure it would be worth the cost to obtain one.

Forward drive works nicely. Reverse drive remains an unfathomable mystery. My son now has a useable roto-tiller. If ever the machine outlives its usefulness, it will be scrap metal. The machine is unsaleable with half of its cylinder head screws missing.

* * *

Note:

[1] This strikes me as an outrageously bad design feature. What were they thinking? To have to disturb cylinder head screws in order to access the ignition system is just

wrong.

# # #

# # #