Model No. is 7800325. Serial No. is 2013045351.

Engine is a Briggs & Stratton 475 Series, 148cc, Model 9T702, Type 0118 B1, Code 0804075.

- - -

It's a nice little basic lawn mower that's been 'worked' on, to no good effect.

The enable/kill bail and cable are missing altogether. The kill switch and brake have been deleted from the engine.

An atrocious installation of a toggle switch for a kill switch has been done.

The muffler has been tampered with for some reason.

The screws are loose, and the anti-loosening bar is out of place. Why on earth anyone would fiddle with a perfectly sound muffler on a small engine is beyond me.

Anyway, the engine won't start. 'Time to check for spark.

Spark Plug Connector

This is a new one on me.

A big, clunky, shielded spark plug connector. I think it may have to do with electromagnetic radiation suppression.

Spark Plug

It's a Champion RJ12C. Hex is 13/16" A/F (across flats). Gap is 0.030". The plug appears to be in quite good condition. Let's see if we have spark.

And there's spark. The engine can be made to run.

- - -

Spark Plug Update -- SUNDAY, MAY 19, 2019

It dawned on me that the RJ12C can't be the correct spark plug for this engine, owing to the fit of the shielded connector. The metal shield on the connector is supposed to reach down to and contact the hex on the spark plug. On the RJ12C, the ceramic is too long for that to happen. The correct spark plug is probably Champion No. RJ19LM.

- - -

Muffler

The loose muffler must be attended to. Here's a view of it off altogether along with its fasteners.

It's a large muffler. I take it that Briggs & Stratton have really made an effort to quiet their engines.

The screws are special shoulder screws, 1/4"-20 x 2 3/8". The threaded portions are 1/2" long. The hex heads are 7/16" A/F. I'll reinstall the whole affair with anti-seize compound on the screw threads.

- - -

Fuel Tank

There's some fuel in it. I can see little globules of water down in the bottom.

I've cleaned and rinsed the tank with solvent, and left it by the furnace to thoroughly dry out. I may take a hair dryer to it to see if I can get it dried out quickly.

Governor Vane

The governor vane was sluggish. It was binding because its mounting base (the top surface of the coil's laminations) was dimpled. I filed down the length of the vane's pivot sleeve a bit, and reinstalled the vane. Now it's fine -- it pivots freely.

Carburetor

'Cleaned and flushed and blew it dry. The diaphragm looks marginal. I'll try reusing it and see how it goes.

- - -

It Starts And RunsFresh gasoline in a clean tank and carburetor and away it goes.

Now I have to decide how much to put into this machine regarding the enable/kill function. I'll seek my son's advice.

- - -

Update -- SUNDAY, MAY 26, 2019

I looked into the cost of reconstructing the enable/kill bail function, and I can't see going ahead with it -- it would be too costly. I could simply do a nice installation of the toggle switch, and the mower would certainly be useable, but I don't want to be selling gear that doesn't comply with currently mandated safety standards; that would be asking for trouble. So, the mower can go languish at the bottom of the backyard for now. Perhaps I'll come across a similar mower that's an utter ruin but for its enable/kill components. Then I could rob parts from it, scrap what's left and get this pretty nice Murray machine in good order.

- - -

Update -- WEDNESDAY, JULY 3, 2019

I decided to be optimistic about the possibility of obtaining the parts for the mower's enable/kill function, and go ahead with refurbishing the deck.

I stripped everything off the deck, and pressure washed it. The deck is rusty underneath, of course, but it's sound. The pressure washer did a pretty good, albeit imperfect, job of stripping away the flaking paint from the underside of the deck. The underside finish is unimpressive -- just one thin coat of black enamel.

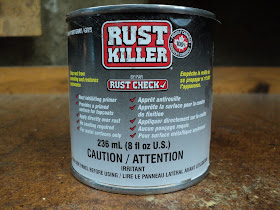

For an underside primer, I got a can of this stuff.

It's basically a grey primer. The price is outrageous -- $10.99 CDN for a little 1/2 US pint can. When I've used that up, I think I'll stick with Tremclad's grey primer; the price is halfway reasonable compared to the Rust Check product, and for all I know it's just as effective.

After priming, I applied two coats of Tremclad gloss black. We have a couple of sunny days ahead, so I've left the deck out on the lawn for the paint job to age in the sun and the free air.

Once that paint job has hardened sufficiently, I'll reassemble the machine and resume pursuing the enable/kill function components.

- - -

Kill Switch Update -- WEDNESDAY, OCTOBER 9, 2019

For want of anything better to do, I went ahead and did a proper installation of the kill switch.

The switch's 'L' bracket is from 3/4" steel strapping, with a 15/32" hole drilled in it to accept the switch's shank. The ground terminal and cable clamp fasteners are 10-32 x 1/2" screws.

# # #

# # #

No comments:

Post a Comment