Well, what have we here?

A $2.00 garage sale find that's missing its air cleaner. Hmmm.

There's no I.D. plate on it anywhere that I can find. I think it's a model No. RY09466. I found an operator's manual for that model on-line, and downloaded it and saved it.

This is a four-stroke cycle machine. I'll check the oil, and find the spark plug and check for spark.

Engine Oil

The sump is empty -- not a good sign, although the engine certainly isn't seized.

According to the operator's manual, the engine takes 65ml of 20W-50. I have sufficient SAE 30 on hand, which the manual also permits the use of. I won't fill the sump until I've confirmed that there's spark. If there's no spark, this thing is landfill.

Spark Plug Access/Spark Plug

Remove the right side cover to begin to gain access to the spark plug. You'll need a T20 Torx driver.

There are four No. 8 x 11/16" threading screws, and one M4 special shoulder screw that secure the cover. Remove the five screws to get to here.

The spark plug is a Champion RY4C. Gap is 0.025". Hex size is 5/8" A/F.

The plug is awkwardly situated toward the front of the engine, like so.

In order to get a socket wrench onto the spark plug, you have to remove the right side of the handle.

Remove three No. 10 x 3/4" threading screws (T25 Torx recess). Watch out for a little steel rod part (a ground wire) at the top of the handle -- it will be free to fall out once you take away the right side of the handle. Here's a view of the machine with the right side of the handle off, and a spark plug socket in place.

The socket wrench is a snug fit -- there's just room enough to get it in place.

Here's a view of the plug out of the cylinder head, and in position for testing.

The spark plug works, in spite of its somewhat fouled appearance. I'll clean and gap it, and reinstall it. Then I'll fill the sump with SAE 30 and try starting the engine.

- - -

With some fresh fuel, and after much fiddling about and starter yanking, I got it to start and run for awhile. It finally stalled on me, and it doesn't like to restart when it's hot -- it seems to want to sit for awhile, then go through the whole cold start procedure again.

It blows a fair amount of smoke, and the throttle linkage has a lot of slop in it. This machine probably has many hours on it, and really isn't worth the price of a carburetor diaphragm kit.

[1] But, it's not as though I have lots of job interviews lined up, so I may look into it further if only to learn more. We'll see.

- - -

Fuel Tubing

The fuel tubing is Tygon F-4040-A, 3/16" O.D. Here's a view of the tubing arrangement at the carburetor and fuel tank. (Fortunately, the tubing on this machine is still reasonably sound. Fuel line tubing embrittlement failure is common on years-old engines.)

Note the following:

a) Bottom-most carburetor nipple to front-most fuel tank hole is the fuel supply to the carburetor.

b) Carburetor right side nipple to primer bulb left side nipple is primer suction.

c) Primer bulb right side nipple to rear-most fuel tank hole is fuel return to the tank from the primer bulb.

Carburetor Removal

1) Air Cleaner Cover off.

2) Engine Right Side Cover off.

3) Right Side of Handle off.

4) Throttle Cable Anchor removed from air cleaner body. Throttle Cable disconnected from throttle crank.

5) Crankcase Ventilation Tube disconnected from air cleaner nipple.

6) Primer Return Tube disconnected from right side primer bulb nipple.

7) Primer Suction Tube and Fuel Supply Tubes disconnected from carburetor nipples.

8) Two M5 Prevailing Torque Hex Nuts (8mm hex).

The air cleaner body and the carburetor are free to come off the engine.

Carburetor

The carburetor is made by Ruixing in China. "129" is embossed on it, and "BFG00970" is printed on it. I can find no specific information on the unit.

I dismantled the carburetor far enough to inspect the diaphragms. The pump diaphragm appears to be quite stiff -- I wonder if that may be the cause of the hot restart trouble.

In any event, if I do go for a diaphragm kit, I'll take the complete carburetor with me. That's always a good practice whenever one is going for carburetor parts.

- - -

Carburetor Diaphragm Kit

It turns out that a Walbro item fills the bill. It's Walbro P/N D11-WYL.

- - -

Valve Clearance Adjustment

The operator's manual says to inspect "camshaft-to-rocker arm clearance" every 25 hours. (You could probably count on the fingers of one hand the number of owners who've ever actually done that.)

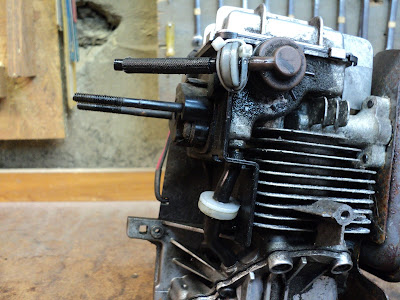

This machine appears to have had a great deal of use, so it might be interesting to see what the state of the valve clearances are. To access the adjustment, first remove the engine's right side cover. That reveals the valve train cover at the top of the engine, like so.

That single cap screw near the centre of the cover is the only fastener involved. Remove that screw (T20 Torx) and you can pop the cover off.

And here's what you'll see.

The gaps are measured between the cam lobes, and the rear ends of the rocker arms. The gaps fully express themselves at a point just beyond Top Dead Centre (TDC) of the compression stroke -- that's where both valves must be fully closed for the power stroke. Use the starter to hand cycle the engine to the appropriate point.

The gap specification is 0.006" to 0.008". for both valves. Use a 0.006" feeler gauge as a 'go' gauge, and an 0.008" feeler gauge as a 'no-go' gauge.

The locknuts on top are 9mm hex; the adjustment nuts' flats are 7mm across. For the adjustment nuts, you would need a thinner-than-average 7mm ignition wrench.

On this engine, the exhaust valve's gap is within spec; the intake valve just barely allows an 0.008" feeler gauge to go. The adjustment is not worth fiddling with, and that's probably the case for the vast majority of these engines over their useful life.

- - -

Final Outcome

This machine is landfill; the compression is so poor that I can't get it to run reliably.

It starts and idles, with the occasional miss. (The spark plug is clean and correctly gapped.) At wide open throttle (WOT), it will run for a little while, then it starts missing and slowing and finally stalls. It won't restart. examination of the spark plug reveals a wet plug tip.

I think what's happening is that the cylinder wall blow-by is so bad that the spark plug is oil-fouling. That's the best hypothesis I can come up with to explain what I've observed.

What I may do yet, just for the heck of it, is tear the engine down completely to get a look at its innards -- that may be an interesting exercise. We'll see.

- - -

Note:

[1] On diaphragm carburetor equipped engines, stiffened carburetor diaphragms are the cause of many starting/performance troubles. Use of ethanol-laced gasoline is guaranteed to result in stiffened diaphragms.

# # #

# # #